technical information

Bricks are the only man-made building materials that testify to their use since the early human civilization. With their attractive appearances and superior properties such as high compressive strength and durability, excellent fire and weather resistance, good thermal and sound insulation, bricks are widely used for building, civil engineering work, and landscape design.

Technical Information

Brickwork Mortars

Mortars have direct influence on the strength, durability and impermeability of brickwork. Mortars also affect the speed of work, hence the laying cost of brickwork. It is therefore important to select and use correctly the right type mortar for any particular application to save labour cost and achieve better quality of brickwork.

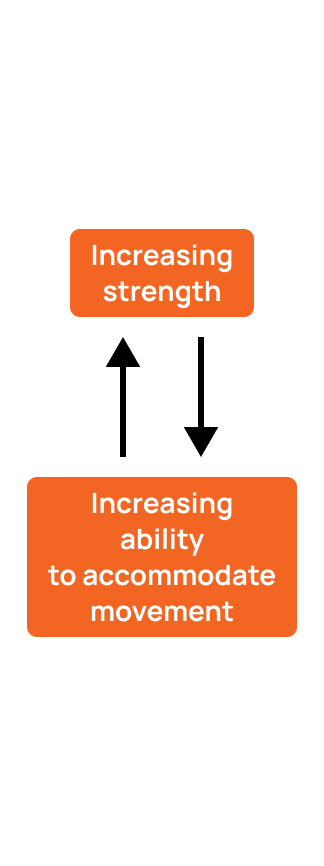

Although mortar forms only a small proportion of brickwork as a whole, its functional performance has a significant effect, in particular, on the movement that affects the structure within the wall itself and with the adjacent parts of the buildings. The function of mortar, besides providing the necessary bonding between bricks, should give sufficient flexural tensile strength. In turn, this will help to relieve the stress and reduce the risk of cracking the brickwork.

Therefore, strict quality control in batching and mixing of mortar plays a vital in brickwork construction.

A good mortar renders the following properties and functions :-

- Good workability to ease laying work and improve quality of the joints

- Good water retentivity to prevent excessive suction of water by bricks that have high initial rate of absorption and retain sufficient water required for hydration of cement

- Development of suitable early and final strength

- Offers water-tightness and durability to a wall

- Good adhesion or bond for bricks

1. Types of Mortar

|

Mortar Grade | Cement : Sand 1 : 3 | Cement : Lime : Sand | Masonry Cement : Sand | Cement : Sand & Plasticizer | Typical Compressive Strength, N/mm2 7days 8 days |

|---|---|---|---|---|---|---|

| 1 | - | 1 : 1/4 : 3 | - | - | 11.0 16.0 |

|

| 2 | - | 1 : 1/2 : 4½ | 1 : 3 | 1 : 4 | 5.5 8.0 |

|

| 3 | - | 1 : 1 : 5~6 | 1 : 4½ | 1 : 5~6 | 2.5 4.0 |

|

| 4 | - | 1 : 2 : 8~9 | 1 : 6 | 1 : 7~8 | 1.0 1.5 |

|

| 5 | - | 1 : 3 : 10~13 | 1 : 7 | 1 : 8 | - | |

|

||||||

2. Selection fo Mortars

| Types of Brickwork | exposure conditions | mortar designation |

|---|---|---|

| External Wall | All | 1 |

| Retaining Wall | All | 1, 2 or 3 |

| Parapet, Free Standing Wall or Below Damp-Proof Course | Severe | 3 |

| Between eaves and damp-proof course | Sheltered or Moderate | 4 |

| Internal Wall and Partitions | - | or |

3. Workmanship Factors That Affect Quality of Brickwork

In practice, brickwork is liable to suffer certain degree of defects due to the following human factors:-

- Incorrect selection of mortar: As a general rule for brickwork, do not use mortar with strength higher than necessary. Investigations show that compressive strength is not a crucial factor in the selection of correct mortar. Instead, the workability, water retentivity and bonding are the more important factors to consider.

- Incorrect cement to water ratio of mortar mix: Workers at job site tend to mix mortar with a highr cement to water ratio in order to ease work. This may have an adverse effect on the final strength and drying shrinkage of mortar. The use of right cement water ratio required for optimizing the degree of cement hydration will thus enhance the strength and impermeability of mortar.

- Incorrect batching and mixing of mortar: Too often mortar ingredients are not batched properly and not mixed uniformly at job site. This will eventually affect the workability and quality of mortar.

- Incorrect jointing procedure: The most commonly seen defects of brickwork arise from incomplete or excessive thick filling of joints. Thick bed joint of 16-19 mm may reduce the strength of brickwork by 30% as compared to the normal 10 mm thickness.

- Disturbance of bricks after laying: Any disturbance of bricks after laying for a while will result in breaking the bond between bricks and mortar and give rise to possible adverse effect on the strength of brickwork.

- Failure to protect work from weather: Newly completed brickwork can be adversely affected by exposure to unfavorable weather conditions such as curing under hot sun and damage by rain. Polyurethane sheets can serve as a cheap mean for whether protection.

4. Materials

4.1 Cement

Portland CementThere are five different types of Portland cement :-

- Type A - ordinary Portland cement

- Type B - fast setting Portland cement

- Type C - low heat Portland cement

- Type D - sulphate resistant Portland cement

- White Portland cement

The strength and durability of mortar depend to a great extent on the type and quality of cement used. The choice of cement is based on the usage requirements and conditions of use. Type A cement is adequate for normal usage. In cases where brickwork is exposed to severe contaminated conditions or under seawater where brickwork is liable to salt attack, Type D sulphate resistant Portland cement is preferred. White Portland cement is only used for making white mortar.

Masonry CementMasonry cement is premixed combinations of Portland cement and other fillings and plasticizing compounds. They are intended to replaced the cement and lime in the conventional mortar. The composition of masonry cement varies with the manufacturer.

4.2 Lime

The function of lime is to give good workability and reduce cracks when used correctly. Only hydrated lime is used in masonry mortar.

4.3 Sand

The sand used for mortar must be clean, free from salt and organic contents. Most natural sand contains a small quantity of clay, which will improve the mortar workability. However, excessive clay content causes high drying shrinkage, low compressive strength and poor bandage in brickwork. Practical limit of clay content in sand should not exceed 10%The grain size of sand has great effects on the properties of mortar. BS 1200 prescribes the limits of particle size distribution. In practice, a 50-50 mix of coarse sand (mean value of particle size at 600 microns) and fine sand (mean value of particle size at 300 microns) gives satisfactory result. Owing to the variation of natural sand and its property, local experience and experiment to optimize the property of mortar is necessary.

4.4 Admixtures

Admixtures are used in mortar to achieve the following purposes :-

- To improve workability

- To modify setting time

- To improve water retentivity

- To improve water-proofing property

There are many commercial cement admixtures that claim to achieve the above improvements. These admixtures contain synthesized polymers that produce amazing improvement in the properties of cement mortar when added in a small quantity. However, these admixtures should be used with care and to avoid negative results due to overdosing and overmixing of mortar.